Item NO.:

AT-A03Order(MOQ):

10 MTPayment:

T/T, L/C, D/PProduct Origin:

Shandong, ChinaColor:

As per CustomizationShipping Port:

Qingdao, China or DesignatedLead Time:

3,000 MT/ Month

Description:

Product Name: 3-Legged Self Support Angle Steel Tower

Type: Telecommunication Tower

Height: 45-70M

Design Software: MS TOWER. ASM TOWER,PLS TOWER,SAP2000 ETC.

Wind Speed: 0--330KM/H

Design standard: TIA/EIA-222-G/F/H

Material: GB/T700: Q235B . GB/T1591: Q355B, Q355C, Q355D.Q420

ASTM A36, ASTM 572, GR50. GR65.SS400

EN/0025: S235JR S235JO S235JZ

EN/0025: S355JR S355JO S355JZ

Certificate: ISO9001:2008 SGS COC

Galvanized: Hot-dipped Galvanized

Galvanization Standard: ASTM A123

Nuts or Bolts: Grade 8.8

Welding Standard: AWS D1.1

Method: CO2 Shielded Arc Welding. Submerged Arc Welding (SAW).

Galvanization Standard of Bolts and Nuts: ISO146 OR ASTM/A153

Life Time: More than 25 years

Supply Ability: 3,000MT Per Month

| Design | ||

| 1. Design Code | AT-L3G-SSA-09 | |

| Structure Steel | ||

| 2. Grade | Mild Steel | High Tensile Steel |

| GB/T 700:Q235B, Q235C,Q235D | GB/T1591:Q345B, Q345C,Q3455D | |

| ASTM A36 | ASTM A572 Gr50 | |

| EN10025: S235JR, S235J0,S235J2 | EN10025: S355JR, S355J0,S355J2 | |

| 3. Design Wind Speed | Up to 250 km/h | |

| 4. Allowable deflection | 0.5 ~1.0 degree @ operational speed | |

| 5. Tension strength (Mpa) | 360~510 | 470~630 |

| 6. Yield strength (t≤16mm) (Mpa) | 355 | 235 |

| 7. Elongation (%) | 20 | 24 |

| 8. Impact strength KV (J) | 27(20°C)---Q235B(S235JR) | 27(20°C)---Q345B(S355JR) |

| 27(0°C)---Q235C(S235J0) | 27(0°C)---Q345C(S355J0) | |

| 27(-20°C)---Q235D(S235J2) | 27(-20°C)---Q345D(S355J2) | |

| Bolts & Nuts | ||

| 9. Grade | Grade 4.8, 6.8, 8.8 | |

| 10. Standards for mechanical properties | ||

| 10.1 Bolts | ISO 898-1 | |

| 10.2 Nuts | ISO 898-2 | |

| 10.3 Washers | ISO 6507-1 | |

| 11. Standards for Dimensions | ||

| 11.1 Bolts | DIN7990, DIN931, DIN933 | |

| 11.2 Nuts | ISO4032, ISO4034 | |

| 11.3 Washers | DIN7989, DIN127B, ISO7091 | |

| Welding | ||

| 12. Method | CO2 Shielded Arc Welding & Submerged Arc Welding(SAW) | |

| 13. Standard | AWS D1.1 | |

| Marking | ||

| 14. Method of marking of the members | Hydraulic Press Stamping | |

| Galvanizing | ||

| 15. Galvanization standard of steel sections | ISO 1461 or ASTM A123 | |

| 16. Galvanization standard of bolts and nuts | ISO 1461 or ASTM A153 | |

| Test | ||

| 17. Factory test | Tensile test,Elements analysis, Sharpy test(impact test), Cold Bending, Preece test,Hammer test |

|

| Capacity | ||

| 18. Maximum Production Capacity | 3,000 TON per Month | |

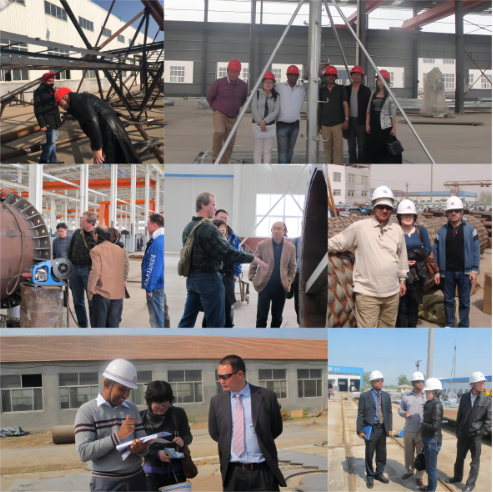

Our Advantages

1.We have a strict quality management system and are certified to ensure that our customers will not have any problems when receiving and using the goods.

2.Imported advanced production equipment can ensure sufficient productivity and good operational stability, ensuring on-time delivery of quality and quantity for our customers.

3.Our long-term accumulation in this industry has given us a good reputation and credibility, and our high-quality products can be seen in major regions of the world.

Full Experience in the Industry

Precision Equipment

Large-scale laser cutting equipment can make the parameters of accessories on the tower smaller. Coupled with professional worker operation and technical guidance, excellence will be penetrated into each of our products.

Mature Production Line and Sophisticated Employees

Hot-dip Galvanization:

Hot-dip galvanization thickness over 100 microns, having strong anti-rust and anti-corrosion capabilities and strictly according to ASTM A123 standard.

Professional Technical Engineering Team

Packaging Details: