About Us

Specializing in the Design, Manufacturing, and Installation of Steel Towers and Communication Structures

Established in 2003, Qingdao Altai Tower Co., Ltd. is a comprehensive enterprise integrating R&D, design, production, and engineering services. With a registered capital of 10 million RMB and over two decades of industry expertise, we have grown into a leading manufacturer of steel structures and telecommunication towers in China.

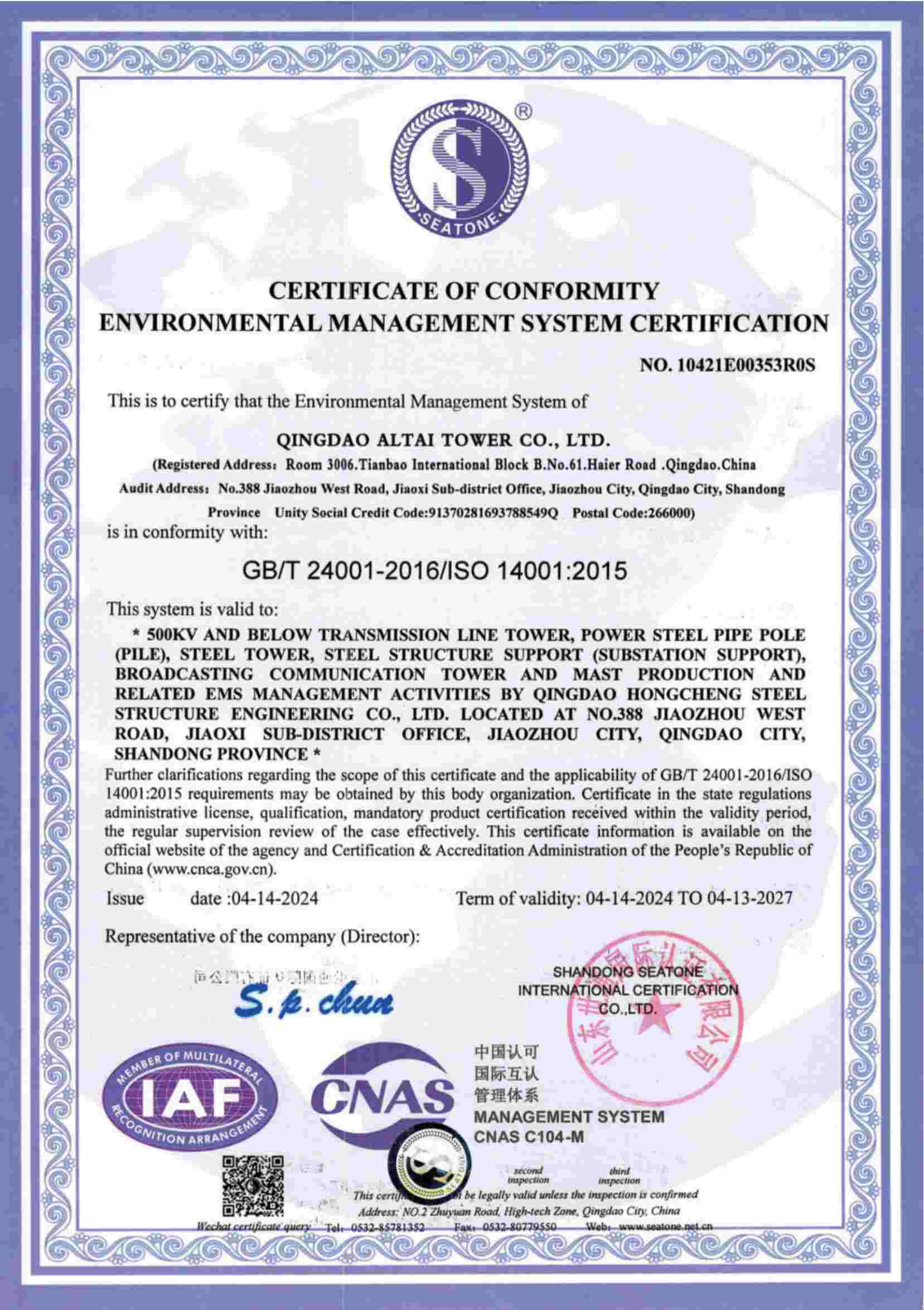

We are ISO9001, ISO14001, and ISO45001 certified, and hold multiple national patents and honors, demonstrating our commitment to quality, environmental responsibility, and innovation.

✓ Telecommunication Towers (Monopole, Lattice, Guyed, etc.)

✓ Transmission Line Towers & Substation Structures

✓ Mobile Telecom Tower ( Cellular on wheels COW)

✓ Lighting Poles, Camera Poles, and Traffic Signal Structures

✓ Customized Steel Structures & OEM/ODM Services

We emphasize engineering integrity, from design and fabrication to installation and maintenance. Our factory-direct model ensures competitive pricing, timely delivery, and reliable after-sales support.

In the field of industrial manufacturing, advanced equipment and precise processes are the cornerstone of superior product quality. Our steel tower production line is a vivid embodiment of this philosophy. We have built an industry-leading intelligent manufacturing system, integrating large-scale precision machining, automated welding, and cutting-edge anti-corrosion technology. By leveraging technology to empower production, we ensure that every steel tower possesses an indestructible structure.

And we have advanced design software in the world, such as: MS Tower, ASM Tower, PLS Tower, SAP 2 0 0 0, etc.

High-precision CNC Cutting and Bending: Our production line is equipped with high-power CNC laser cutting machines that can precisely cut, drill, and bevel steel plates like a skilled tailor. The cutting error is controlled within 0.05 millimeters, thinner than a human hair, ensuring absolute precision of components from the very beginning. For critical structural components, we utilize a 4000-ton hydraulic CNC bending machine and advanced rapid bending devices to efficiently and accurately complete bending operations at various complex angles, meeting the high-strength and high-precision requirements of large components for products such as ultra-high voltage transmission towers.

Automated Welding Workstation: Traditional welding relies on manual expertise, but our workshop is equipped with multiple intelligent welding robots. These robots are equipped with vision scanning and arc tracking systems, allowing the welding torch to operate stably along the optimal path. This not only frees workers from strenuous and hazardous environments but also ensures uniform and smooth welds with minimal slag, resulting in stable and reliable welding quality that far surpasses traditional manual welding. For long welds and thick plates, we utilize double-arc, double-wire submerged arc welding machines, achieving efficient and high-quality deep penetration welding.

Intelligent Integrated Production Line: From automatic angle steel feeding and precise punching to efficient cutting, our automated angle steel production line features full-process PLC control. This intelligent integration significantly improves production efficiency while greatly reducing human error and safety risks, ensuring high consistency in the specifications of mass-produced products.

Advanced hot-dip galvanizing workshop: Providing steel with a durable "protective suit."

Steel towers stand tall in mountains and wilderness year-round, and their exceptional corrosion resistance is fundamental to their safe operation for decades. Our fully automated hot-dip galvanizing production line is the ultimate guarantee of product quality.

We are committed to providing customers with the best telecommunication towers and the most professional telecommunication equipment optimization solutions. Many of our products have been exported to more than 100 different countries and regions, such as the United States, Middle East countries, Europe and so on, and have achieved very good market reputation in the local market.

Our sea freight packaging also adheres to high standards. For angle steel towers, we use fixing clamps and non-woven fabric for packaging, and the weight of each bundle is controlled to within 2 tons to ensure that customers can load and unload them easily. Tubular towers and monopole towers also use standard packaging methods, with non-woven fabric and foam cotton for surface protection.

Why Choose Us?

1.We have a strict quality management system and are certified to ensure that our customers will not have any problems when receiving and using the goods.

2.Imported advanced production equipment can ensure sufficient productivity and good operational stability, ensuring on-time delivery of quality and quantity for our customers.

3.Our long-term accumulation in this industry has given us a good reputation and credibility, and our high-quality products can be seen in major regions of the world.

With the launch of the Belt and Road Initiative, international production capacity cooperation, and the launch of projects in Africa and other countries, we are stepping up the layout of routes to welcome international customers in overseas markets. We can together lay a good foundation for the output of subsequent complete sets of intelligent manufacturing production lines, realize the deep integration of the global economy, embed the world industrial chain at a higher level, and complete complementary advantages and achieve a win-win cooperative development.

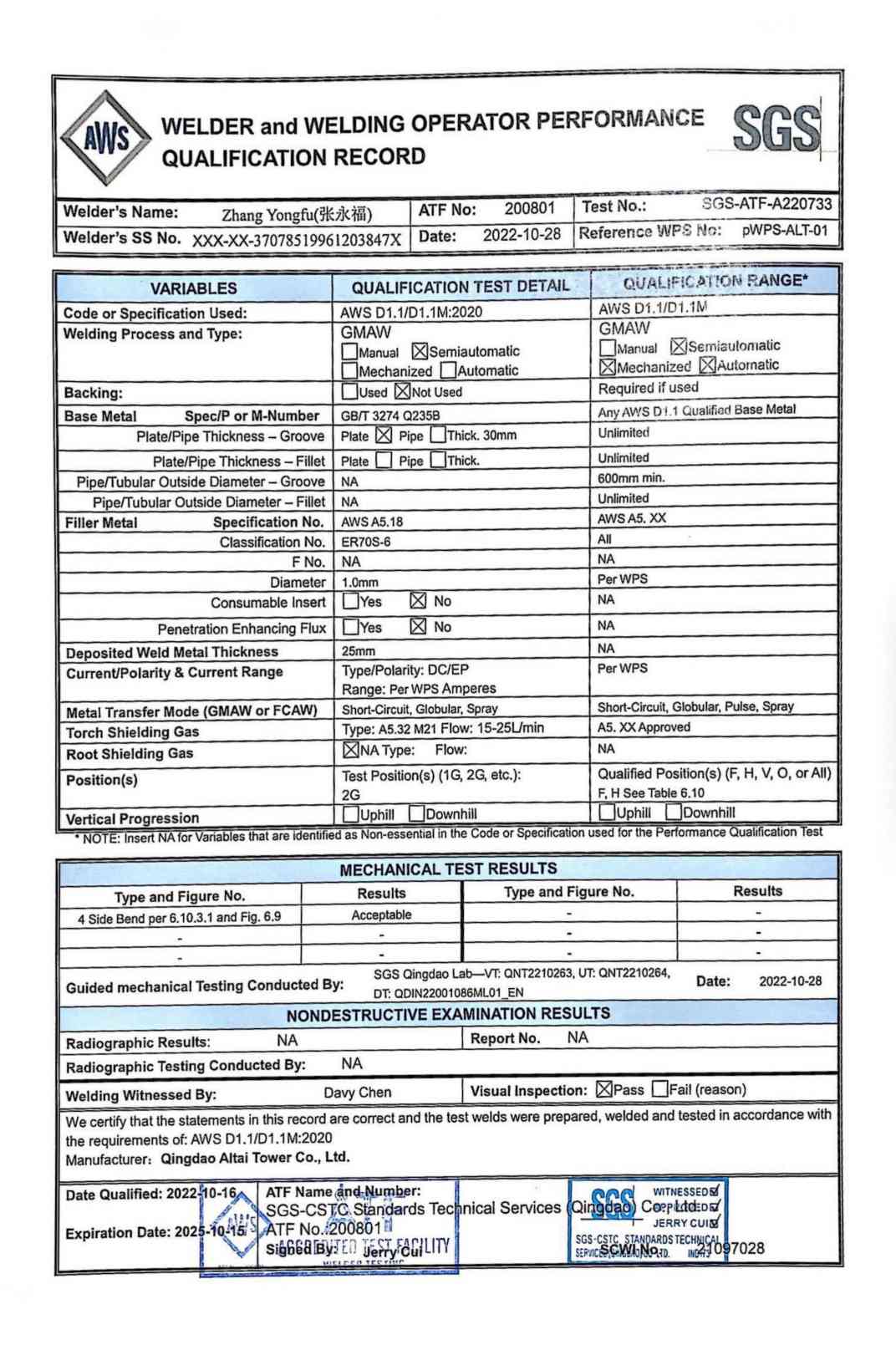

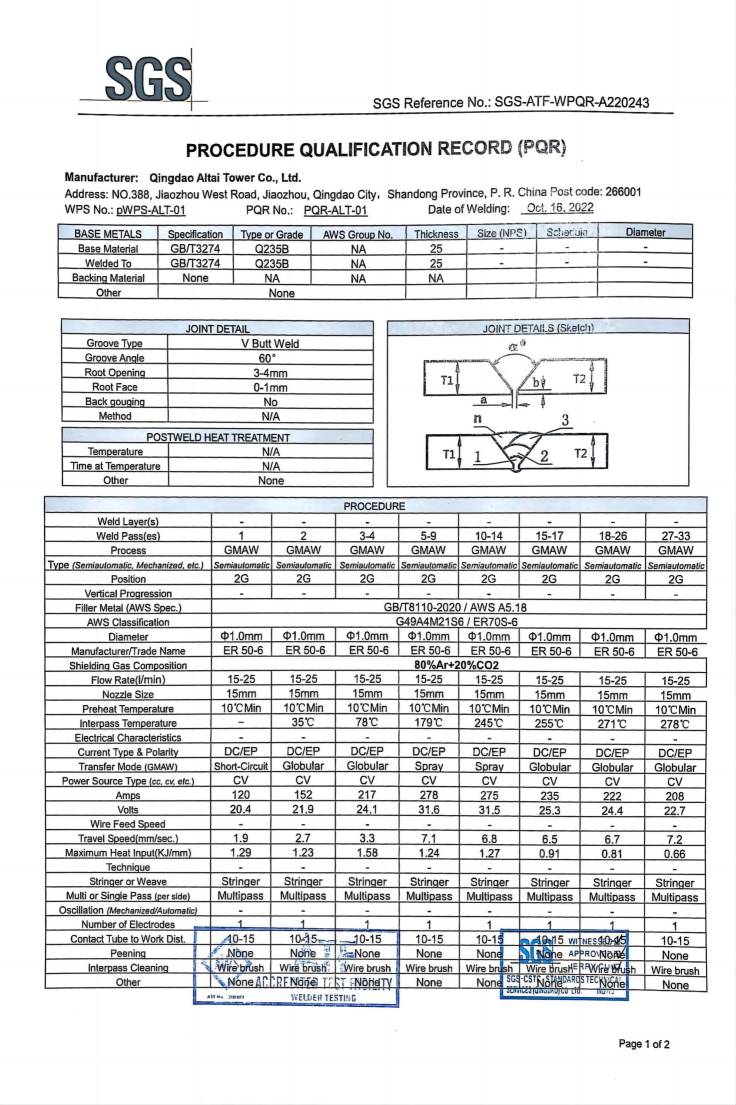

Verifications & Certificates

AWS02

GB/T 45001-2020/ ISO 45001-2018 ( 01)

CE

GB/T 45001-2020/ ISO 45001-2018 ( 03)

GB/T 45001-2020/ ISO 45001-2018 ( 02)

AWS01

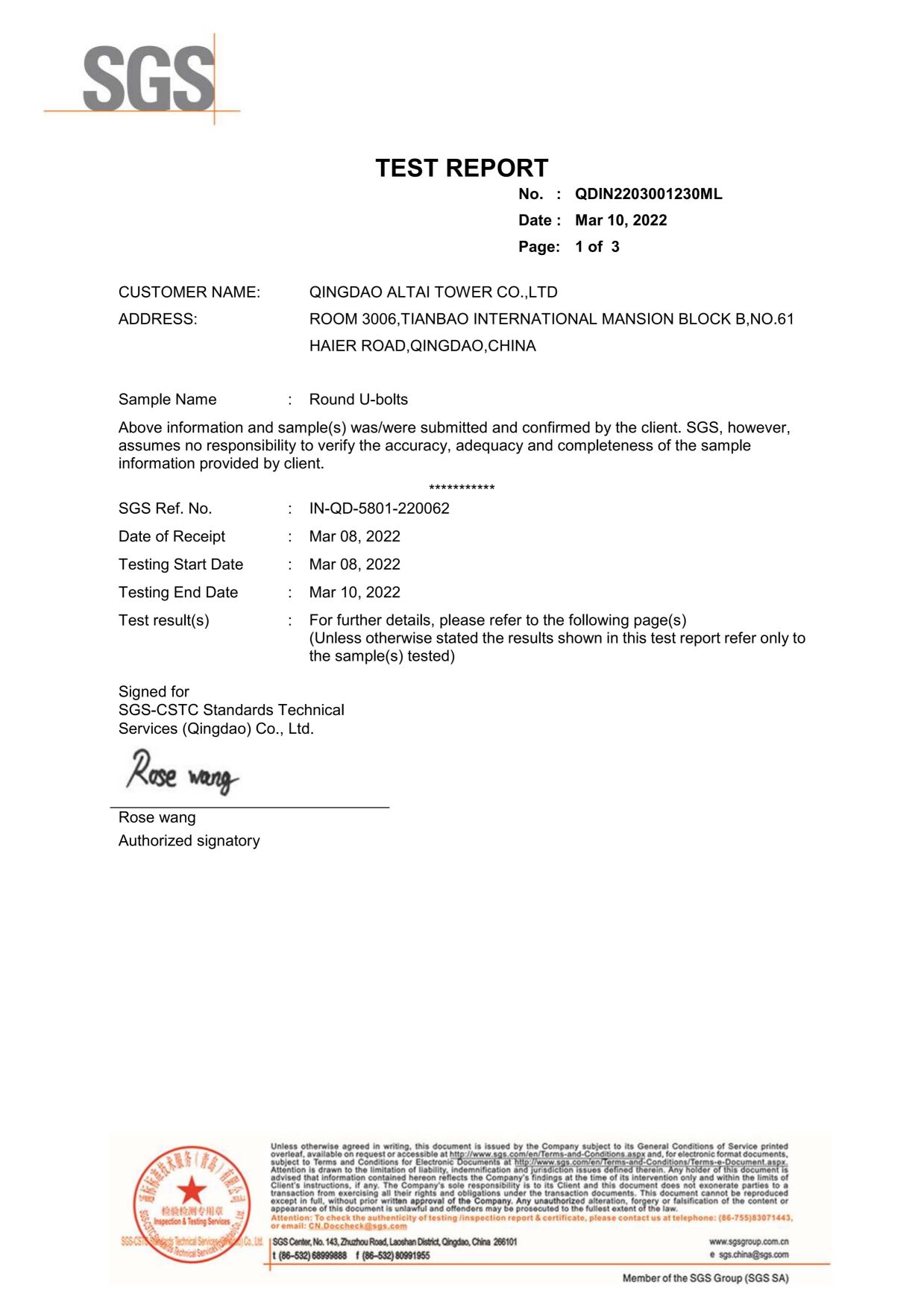

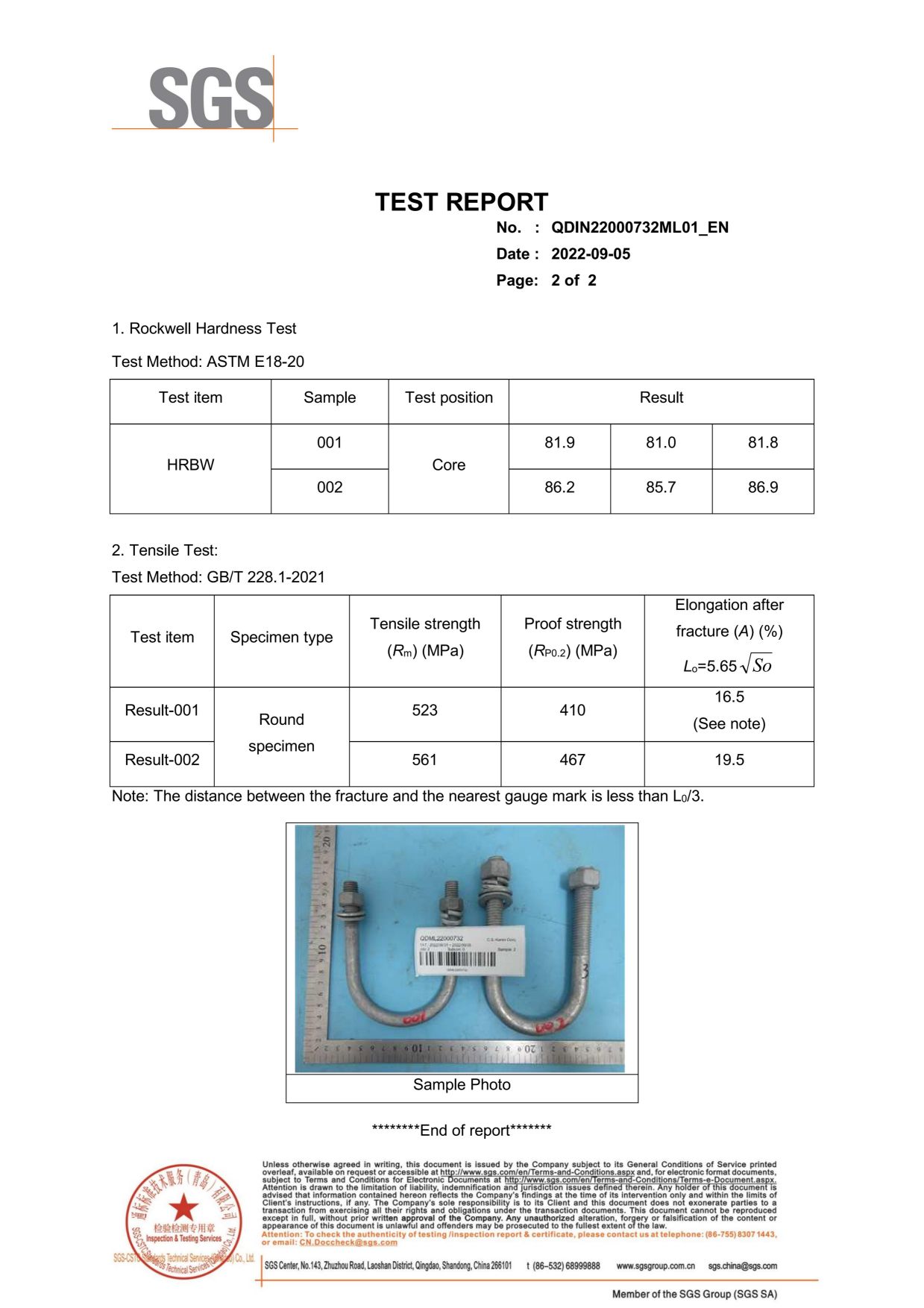

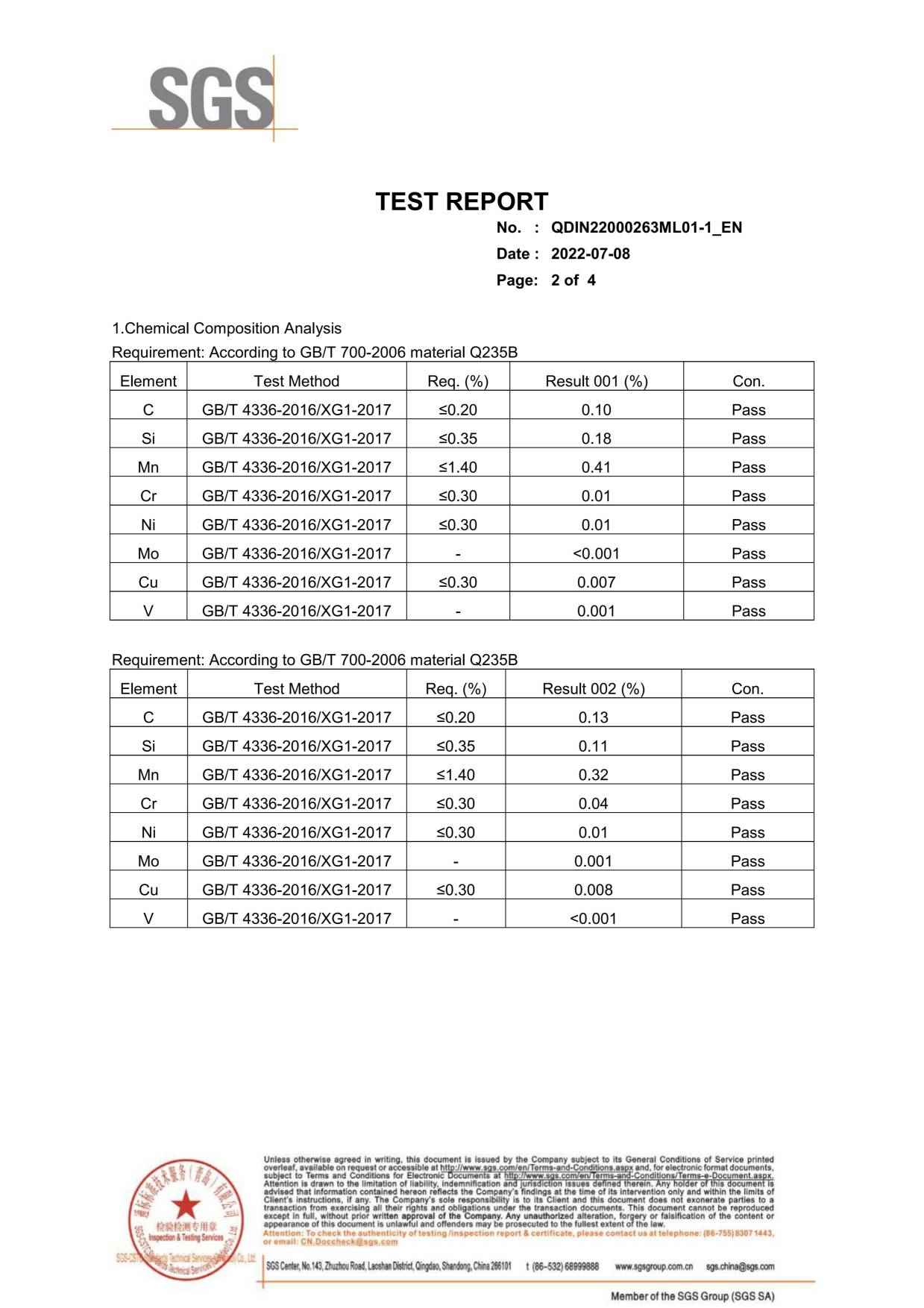

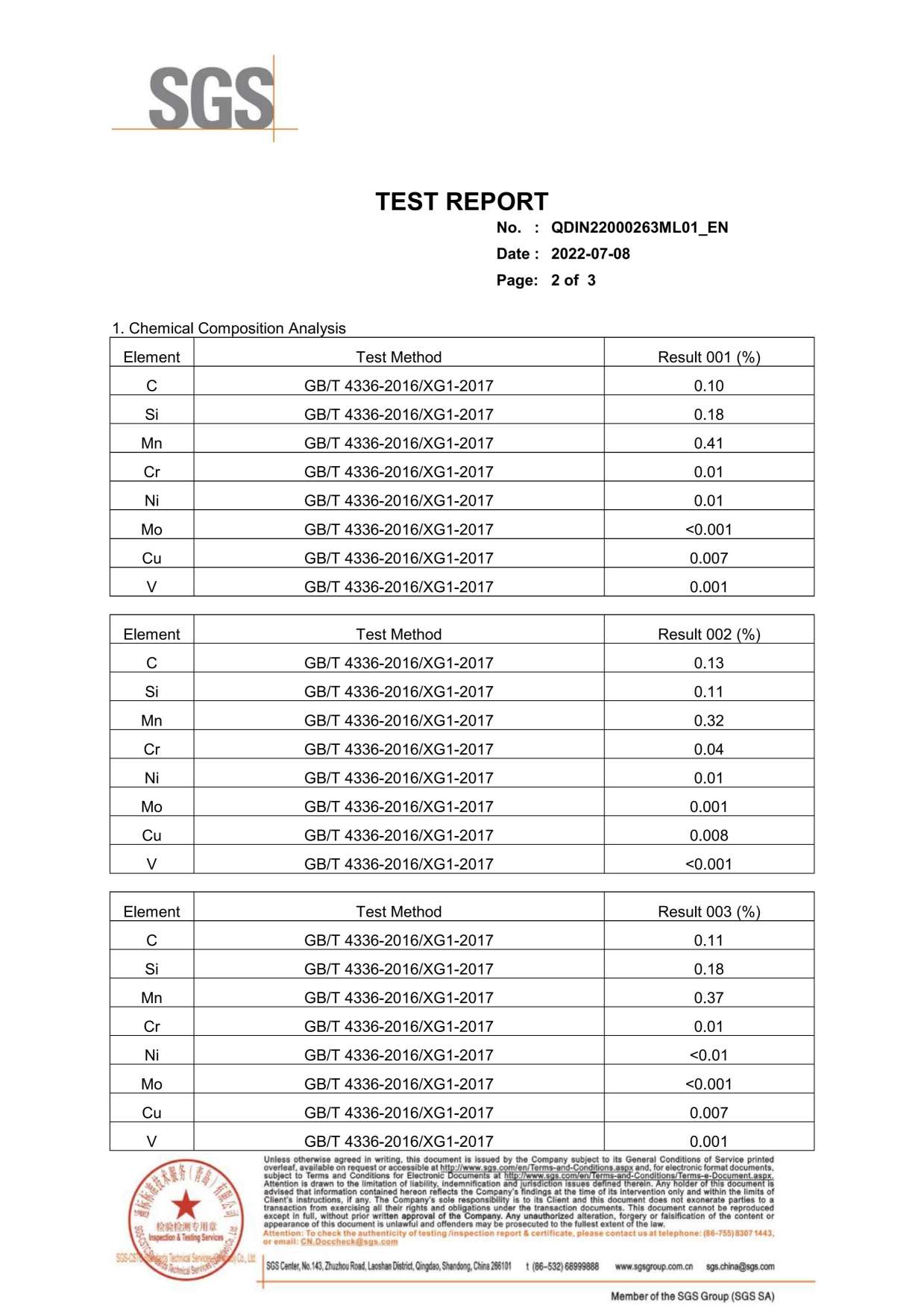

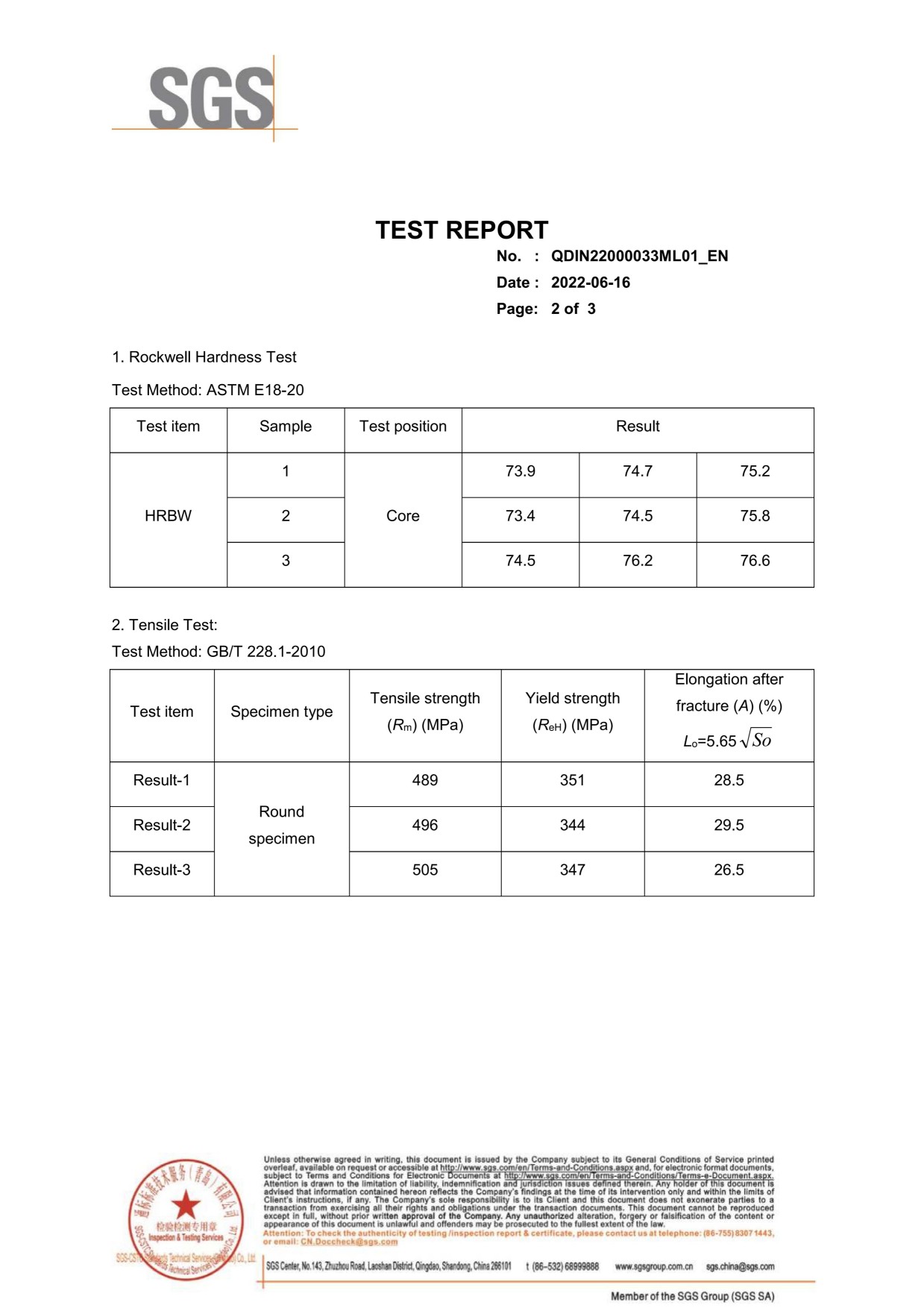

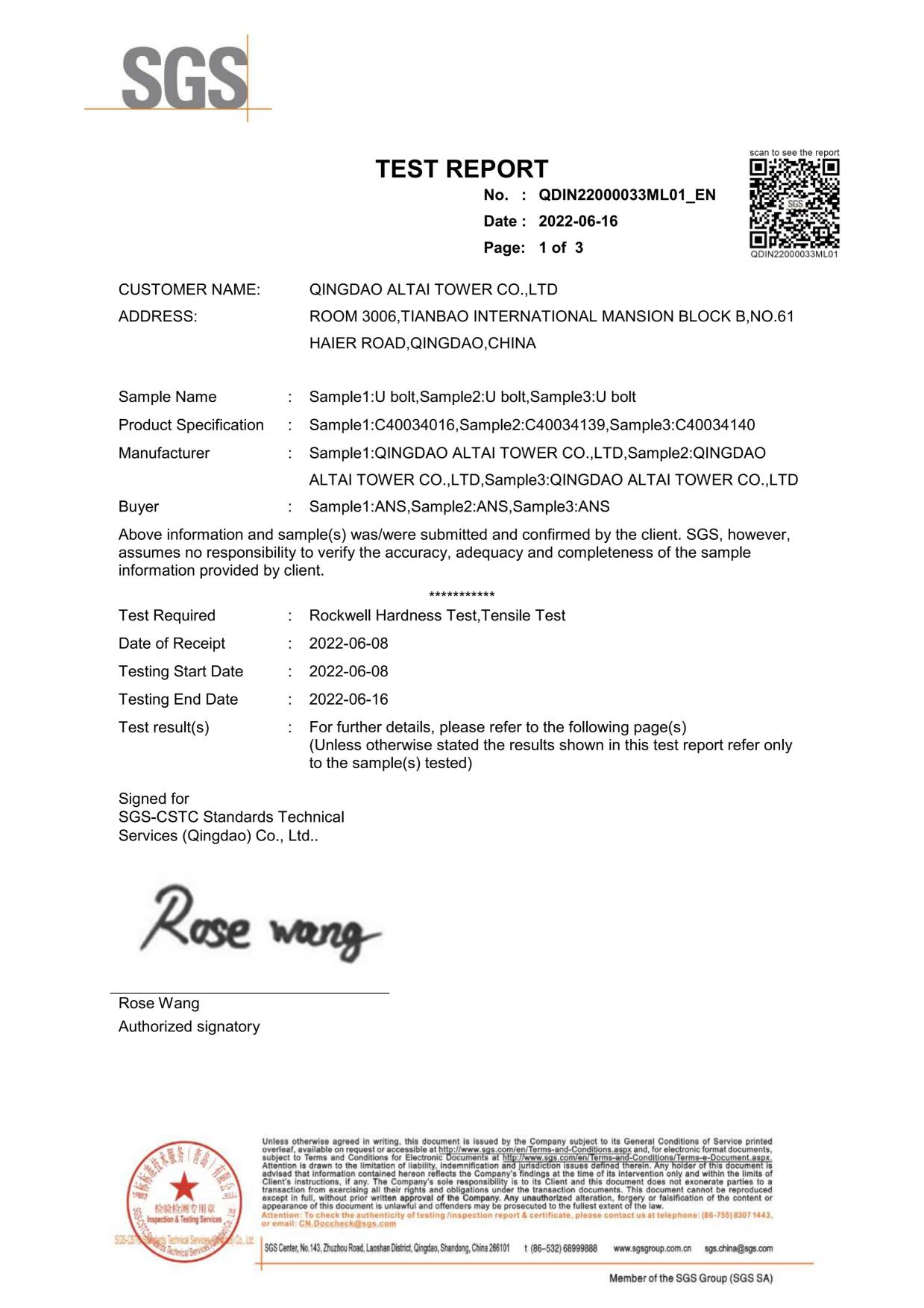

SGS44

SGS33

SGS33

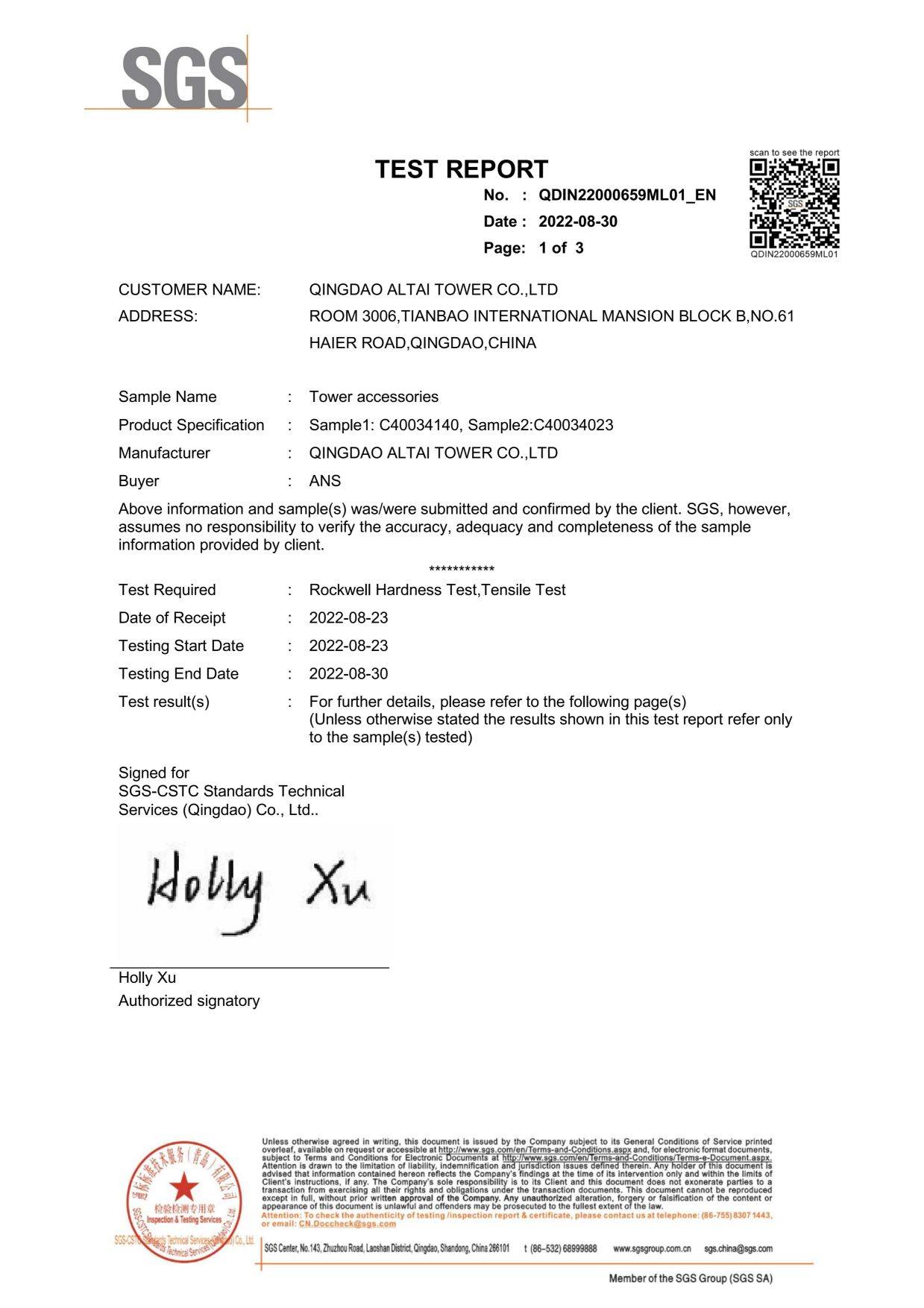

SGS11

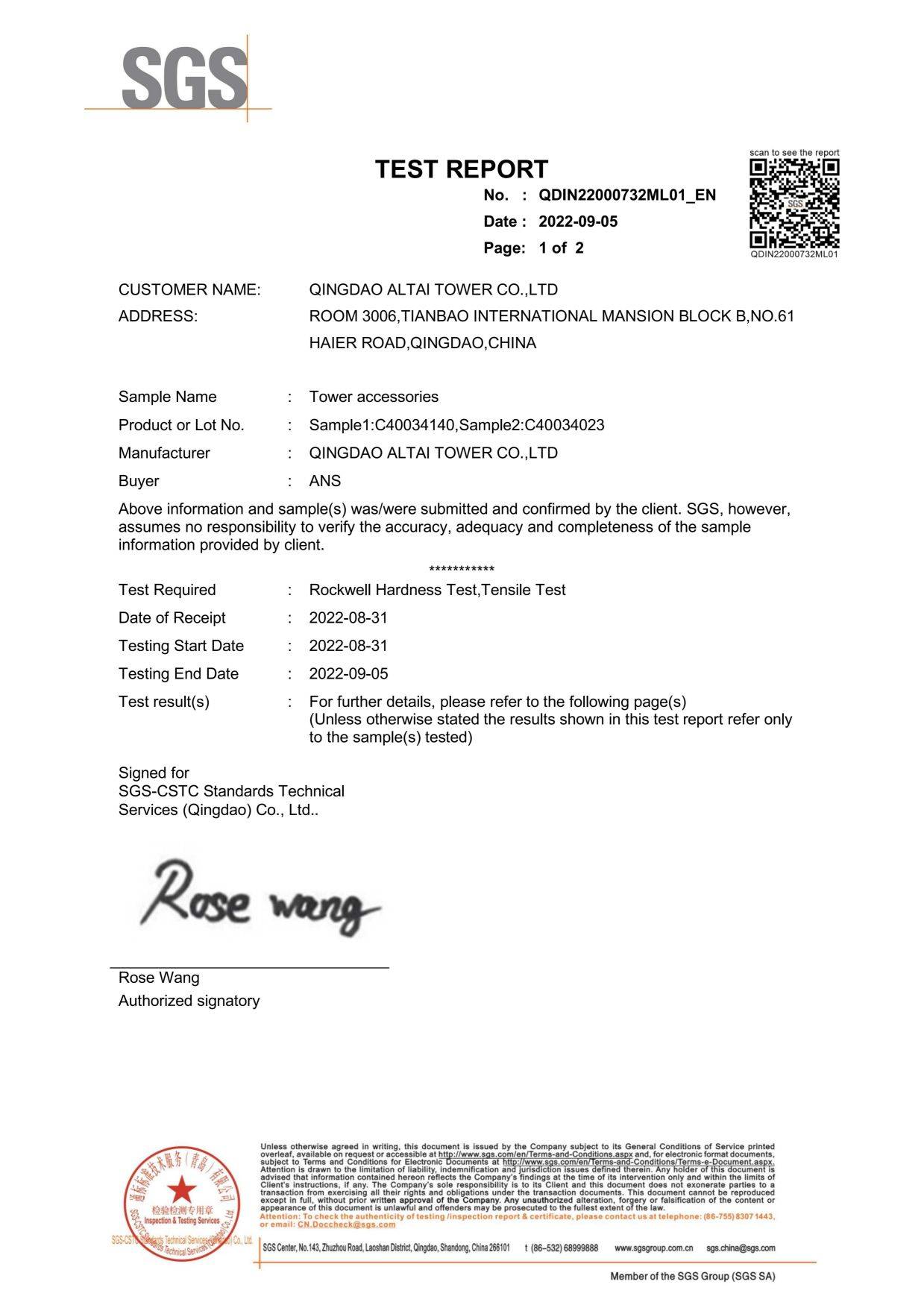

SGS09

SGS9

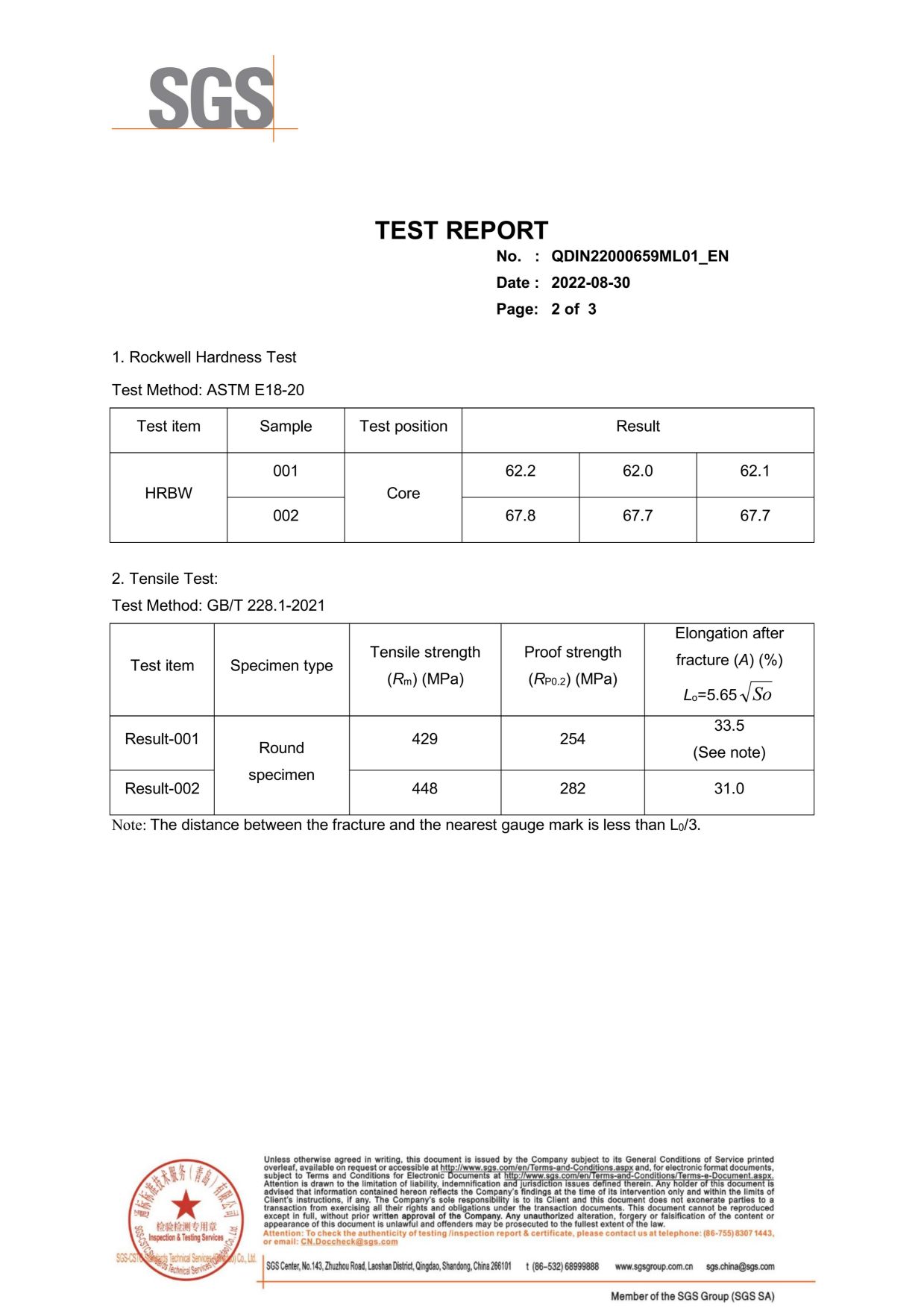

SGS8

SGS7

SGS6

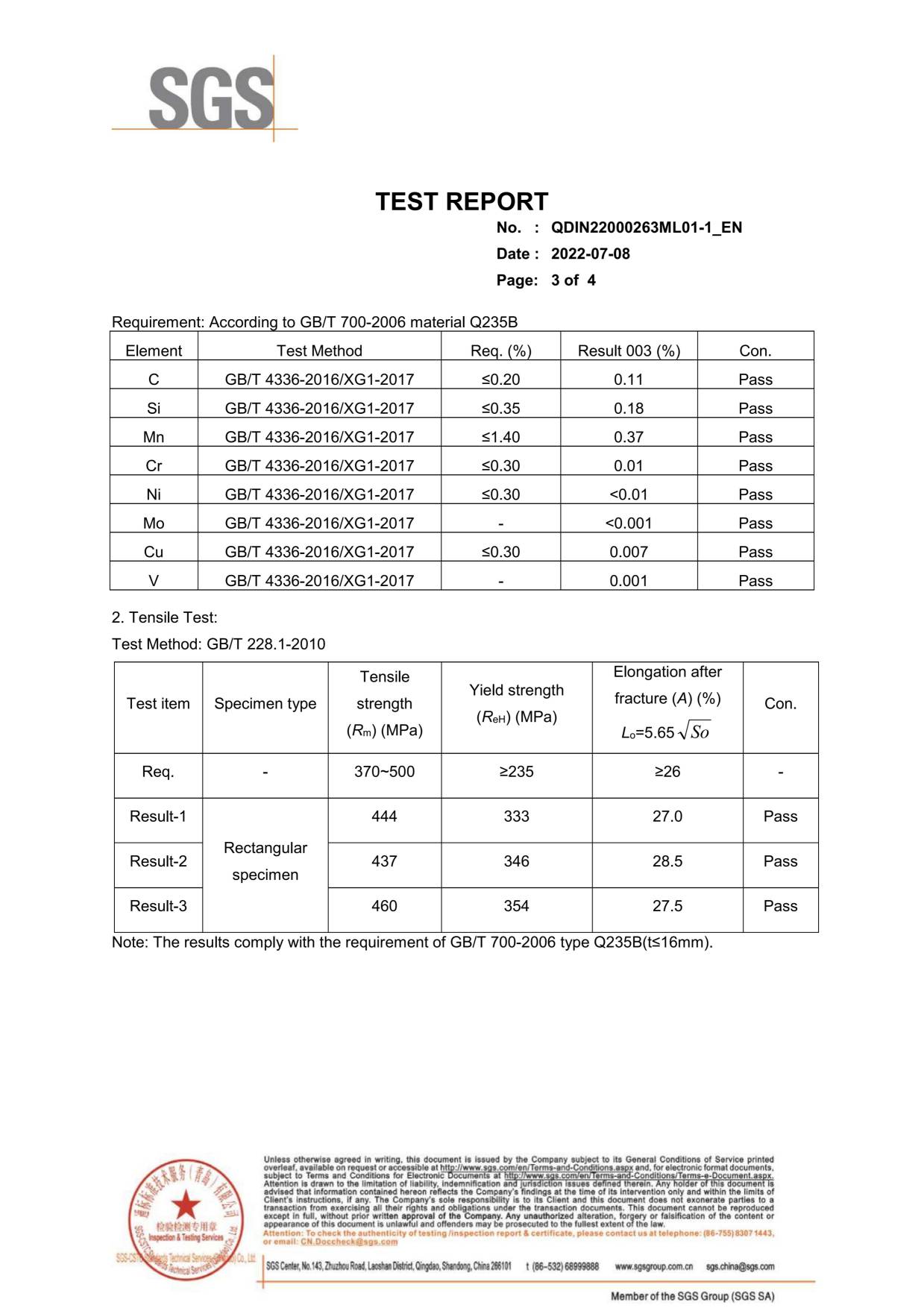

SGS5

SGS4

SGS3

SGS2

SGS1